Strain Wave GearPopular

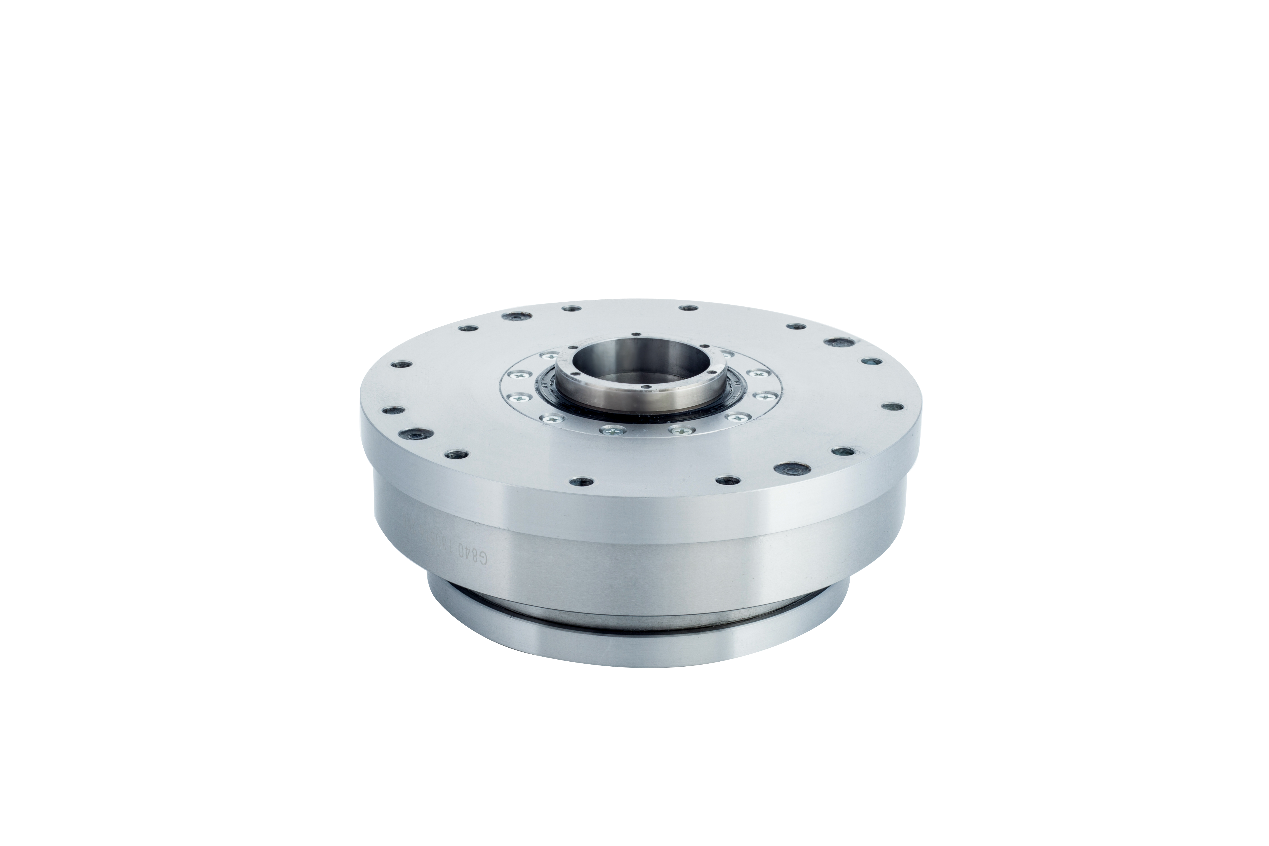

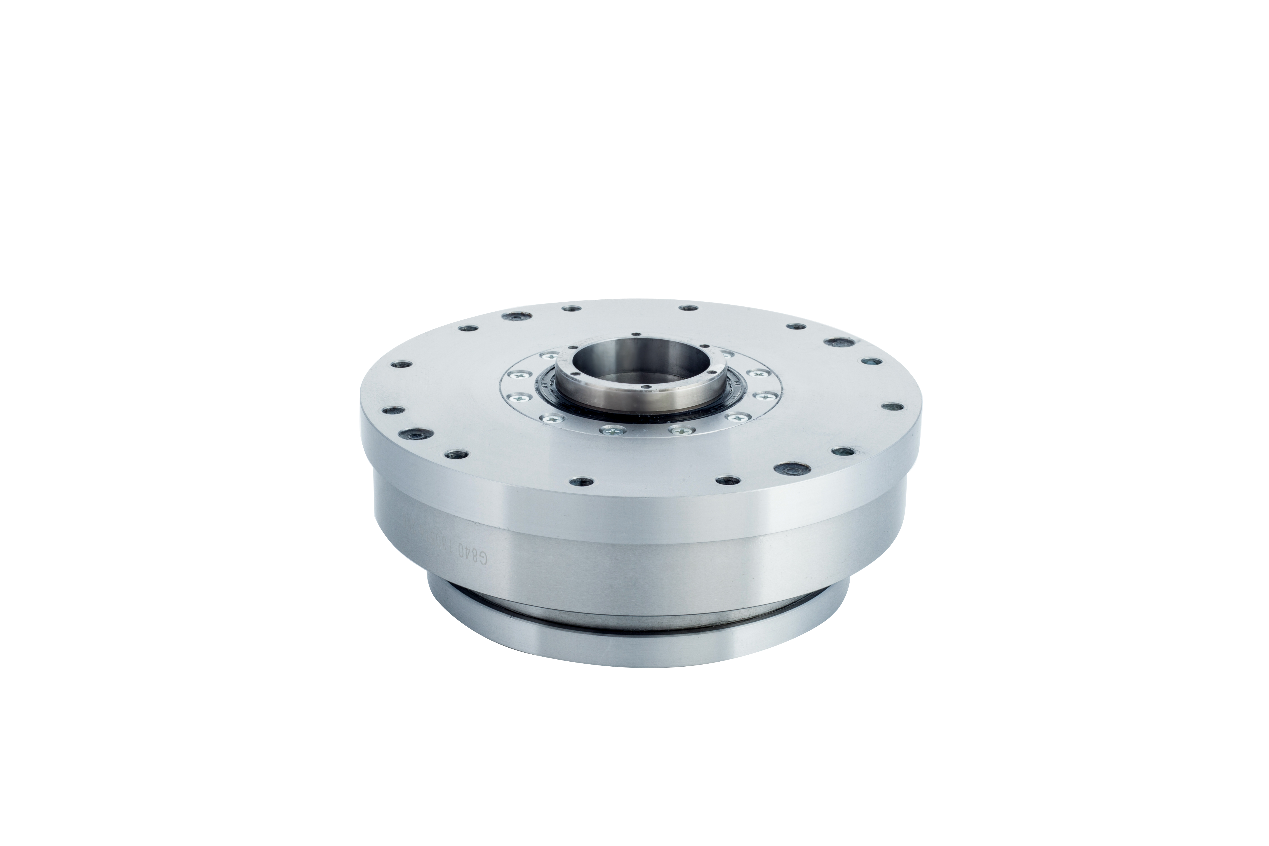

Strain Wave Gear

A harmonic drive, also known as a strain wave gear, is a compact, high-ratio speed reducer and torque multiplier that uses elastic deformation to achieve precise, backlash-free motion, making it ideal for robotics, aerospace, and precision machinery where high accuracy and small size are critical. It works by using an elliptical wave generator that rolls inside a flexible flexspline, causing its teeth to engage with a rigid circular spline (which has more teeth) at two points, creating a significant reduction and smooth, precise movement.

How It Works

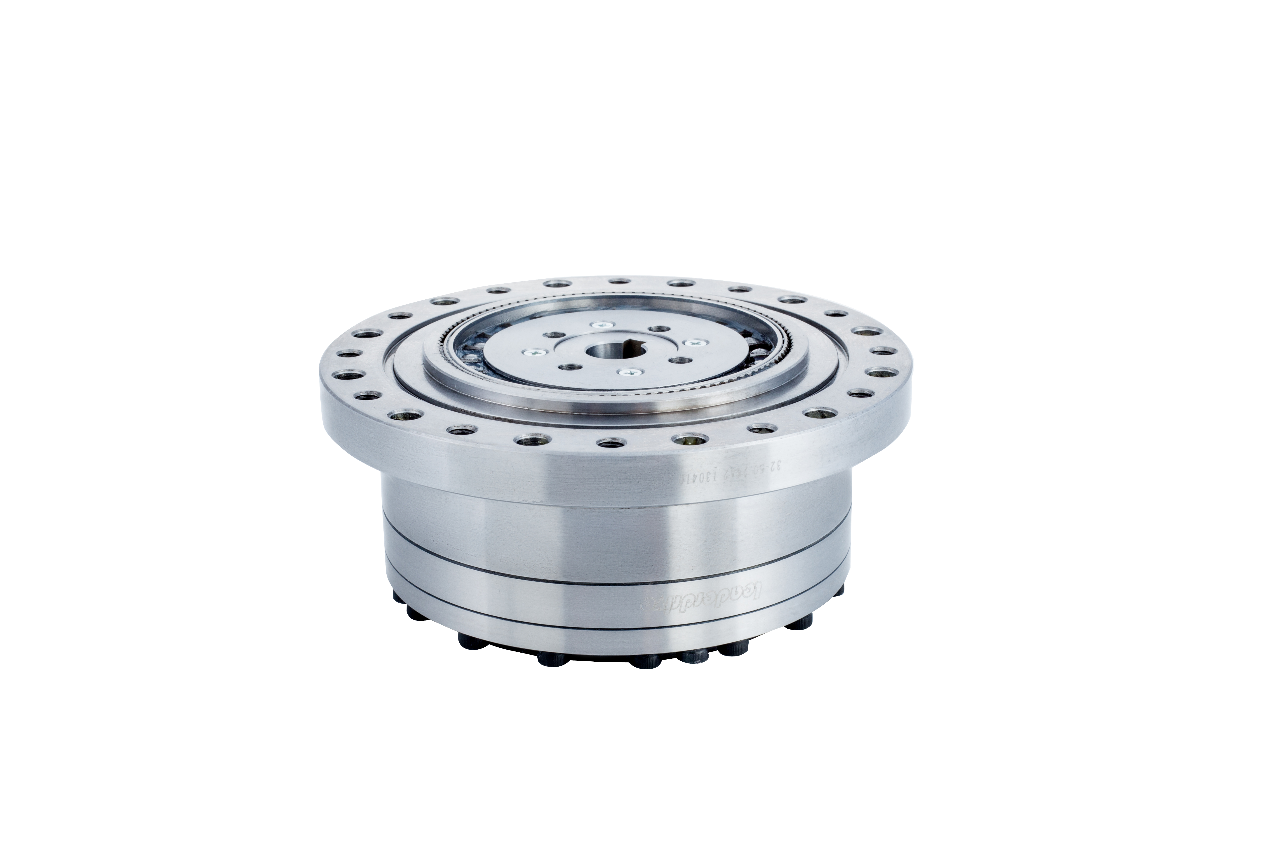

The harmonic drive system consists of only three main components, whose interaction is based on the elastic mechanics of metal.

- Wave Generator: This is the input component, an elliptical cam surrounded by a special, flexible ball bearing. It is connected to the motor shaft and rotates, deforming the flexspline into an oval shape.

- Flexspline: A thin-walled, flexible steel cup with external teeth around its open end. It is torsionally stiff but radially flexible, acting as the output element in most configurations.

- Circular Spline: A rigid ring with internal teeth that is typically fixed to the housing. Crucially, it has two more teeth than the flexspline.

As the wave generator rotates inside the flexspline, it forces the flexspline's teeth to engage with the circular spline's internal teeth at two opposite points along the major axis of the ellipse. Because the flexspline has two fewer teeth, each full rotation of the wave generator causes the flexspline to move only two teeth backward (counter-clockwise) relative to the circular spline, thus achieving a high gear reduction ratio in a single stage.

Advantages

- Zero Backlash: Exact positioning.

- High Gear Ratios: Achieves large speed reductions in a single stage.

- Compact & Lightweight: High torque density for its size, excellent for space-constrained applications.

- High Torque Capacity: Due to multiple teeth being in mesh simultaneously.

Applications

Harmonic drives are utilized across a variety of industries due to their precision and compact design.

- Robotics: Widely used in industrial and surgical robotic arms for smooth and accurate joint movement and high torque density in a limited space.

- Aerospace & Defense: Essential in satellites for positioning systems, antenna controls, and in robotic manipulators for spacecraft due to their reliability in extreme conditions and lightweight nature.

- Medical Technology: Found in surgical robots, imaging systems (CT, MRI), and laboratory automation, where high precision and controlled motion are vital.

- Industrial Automation & Manufacturing: Employed in CNC machine tools, semiconductor manufacturing equipment, and automated material handling for precise motion control.

- Special Environments: Designed for reliable operation under harsh conditions, including extreme temperatures or vacuum environments.